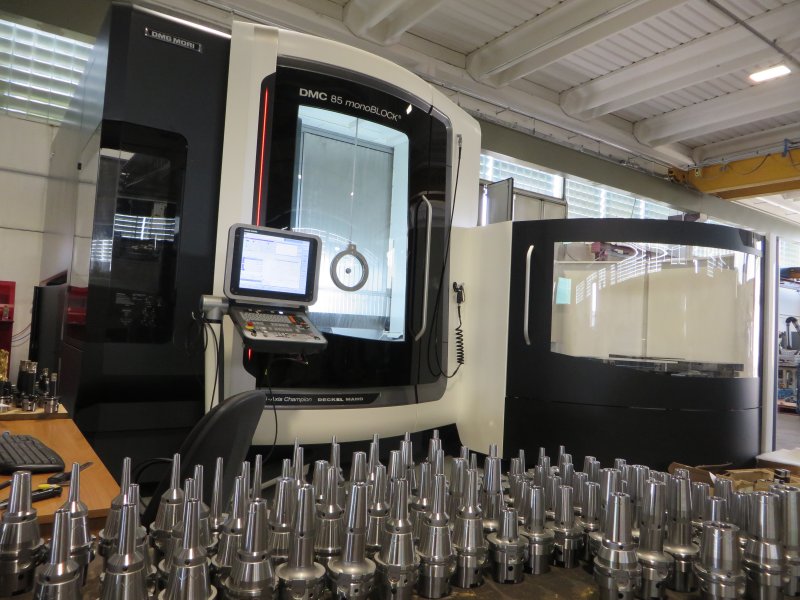

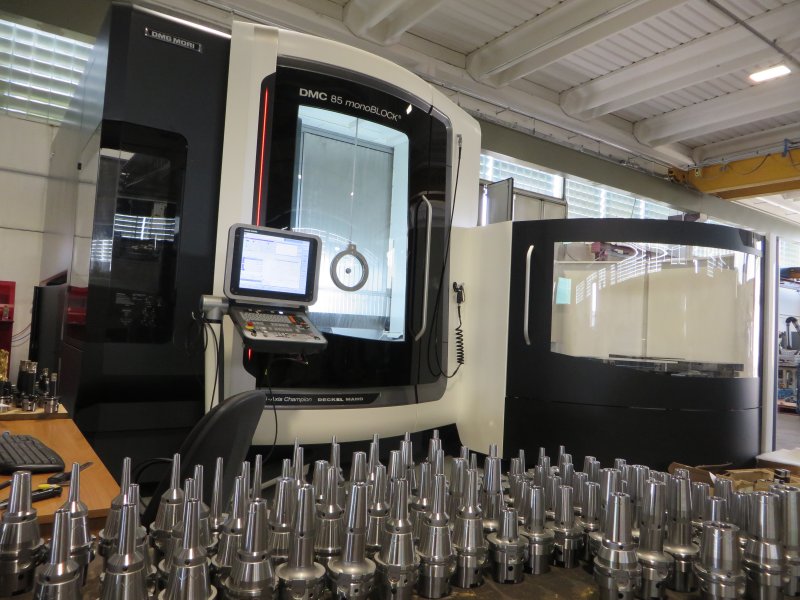

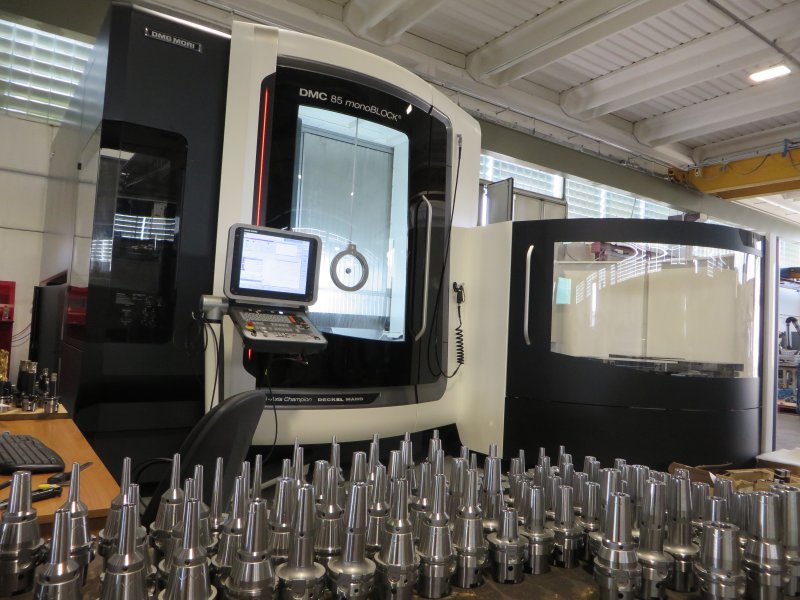

DMC 85 MONOBLOCK

TGS Stampi Srl goes on with his philosophy of investments in new and advanced technologies to achieve faster and faster working phases and walking together with customers demand.

The new milling machine has many advantages, to working out many working phases such us:

Milling

Finishing

Ribs and Undercuts

Drilling

Spot-facing

Threading

The main characteristics are:

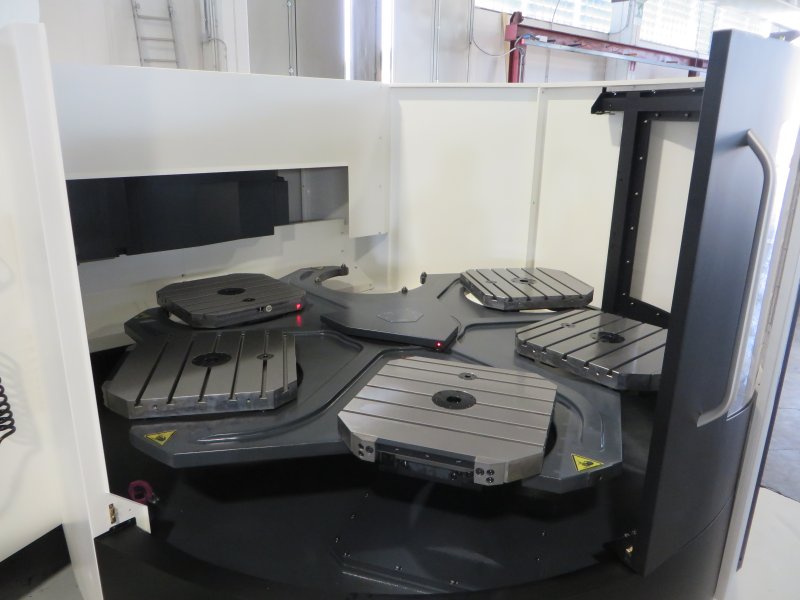

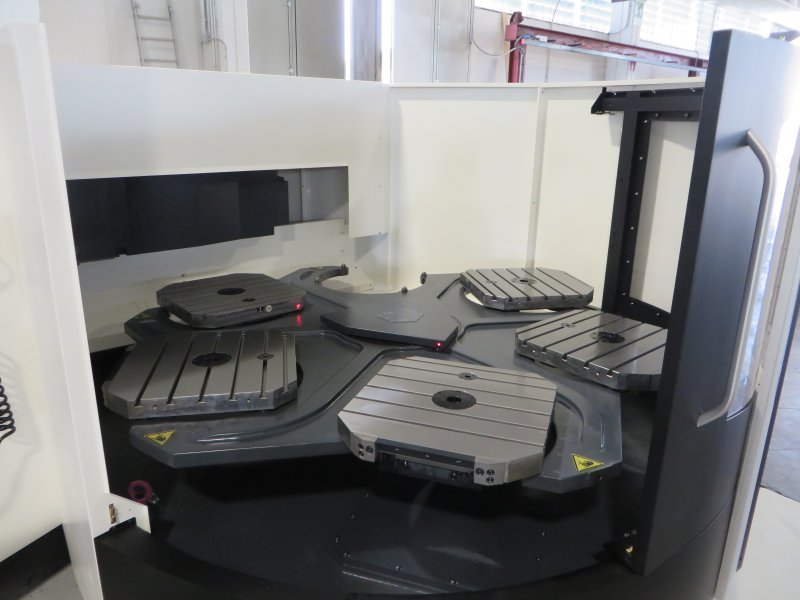

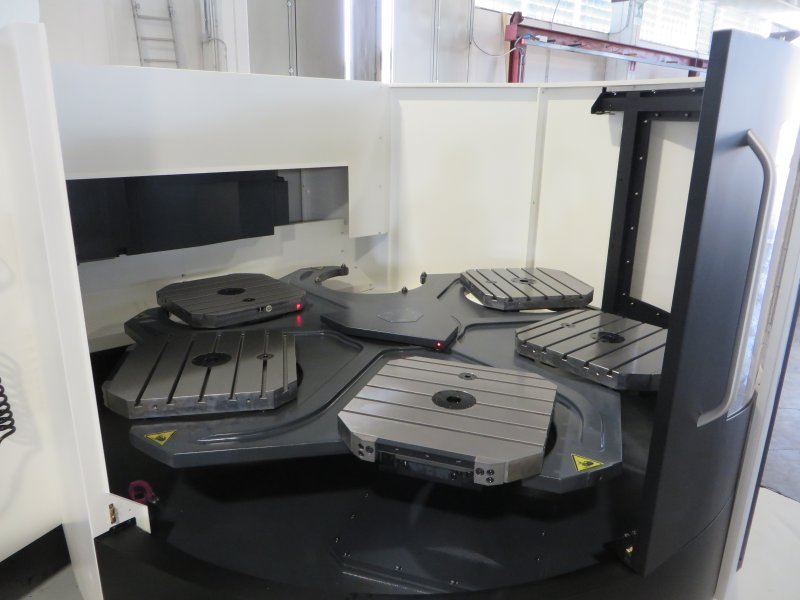

N. 6 pallets with automatic changer system: the part is placed on the pallet out of the machine in the lateral side; by this way the machine can continue to work the other part that is on the machine.

The big advantage is the non-interruption of the production and the H24 continues production.

SWIVELLING and ROTARY Table: automatic rotation of the working parts. It is possible to work n.5 surfaces of the part with only 1 placement.

ROTARY table: 360 °

SWIVELLING table: +120° / -120°

SPINDLE 18.000 rpm

Working with 5 axes continues

120 tools with automatic changer

Drilling liquid up to 80 bar

Maximum load 800 Kg per each pallet loading

Maximum load 1500 Kg per crane loading directly into the working area

Software: Hiedenhain TNC640

Click and open the link to view how it works: https://youtu.be/107KXXJbyHI